Area of expertise espresso is regularly related to small-batch scorching. On the other hand, because the trade grows and matures, many roasters will inevitably scale their operations.

The wish to transfer to a bigger roaster is an important for espresso companies to satisfy the calls for in their increasing buyer bottom. In the United States rejected, the consumption of specialty coffee has increased by 18% between 2020 and 2025, indicating the emerging passion in feature, traceable espresso.

However the transition calls for a lot more than just purchasing a new machine with higher skill. There are lots of elements to believe prior to making the verdict, and roasters wish to get ready themselves for a vital adjustment.

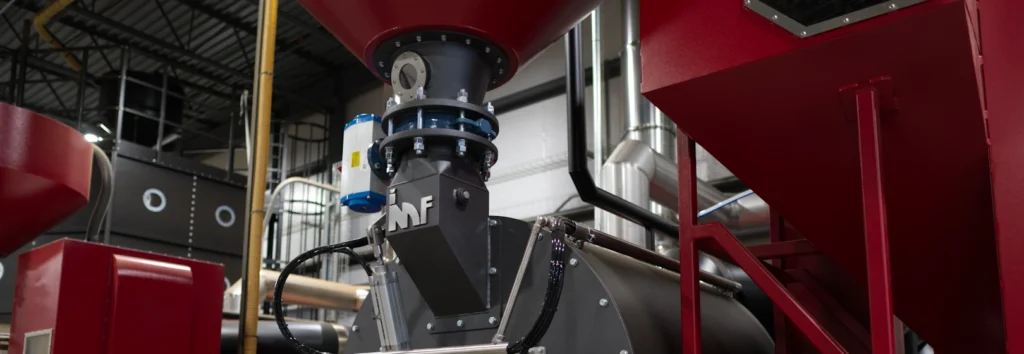

I spoke with Diego Vidiz, a roaster and technical guide at IMF Roasters, concerning the advance roasters jerk when switching from small-batch to large-scale scorching operations.

You might also like our article on designing a complete coffee roasting facility.

Understanding when it’s date to improve a espresso roastery

Maximum roasters regularly set in their companies with extremely streamlined operations, comprising a small-capacity device and only some workforce contributors. However as distinctiveness espresso intake proliferates, including in emerging markets, many companies search to capitalise on its explosive expansion.

Many spend hours studying the bits and bobs of working a roastery, date additionally growing manufacturing processes that mode the bottom of the trade. As soon as a roaster achieves consistency of their product and has evolved sturdy relationships with their core buyer bottom, enlargement turns into a lot more viable.

“With over thirty years working in the coffee industry, I have personally experienced the transition from a small artisanal roastery to a full-scale industrial plant,” says Diego Vidiz, who collaborates with IMF Roasters as a technical guide, supporting the start-up of brandnew scorching amenities. The corporate will show off at WoC Geneva at sales space incorrect. 2264 from 26 to twenty-eight June.

“It’s a shift that doesn’t happen overnight, but there are clear signs when the time comes,” he says. “The first is practical: when production can no longer keep up with orders and roast days are always full, it becomes clear that the current setup isn’t sufficient anymore.”

Discovering the appropriate apparatus

When putting in place a scorching trade, it’s most often really helpful to put money into a device that may accommodate some stage of expansion from the outset.

The use of a roaster that’s too tiny makes it tougher to satisfy massive orders, limiting a trade’ expansion. At the alternative hand, launch with a device that’s too obese manner roastery operators might overestimate their orders, growing possible wastefulness that eats into their prices.

As soon as a roaster establishes the optimum measurement in their device, it’s remarkable to maximise the current setup within the roasting space. Operators will have to believe the location of kit, manufacturing strains, and attic farmlands to streamline workflow and safeguard a a success transition to larger-scale scorching.

“From here, you can attract more structured clients, such as large retailers or international operators, that demand higher volumes and consistent quality,” Diego tells me.

“Internally, the company must also be ready: clear processes, a solid quality control system, and skilled people who can work well as a team are all essential,” he provides. “When these elements are in place, managing significant growth becomes much more feasible.”

What are the principle demanding situations when scaling a espresso roastery?

The transition to the use of massive roasters has its demanding situations.

A vital a part of the artisanal revel in with distinctiveness espresso comes to having near touch with the product itself. Roasters take note of sensory cues within the scorching procedure, akin to color adjustments and listening for ‘first crack’, to know how to keep watch over other variables, and in the long run preserve and fortify feature.

However it’s no longer at all times simple to transform those abilities from tiny to broad batches. Other quantity sizes require various quantities of power to reach the similar effects, which means that some trial and blunder will happen all through the early levels of scaling up.

“The biggest challenge when increasing volumes is maintaining consistent quality,” Diego says. “In an artisanal roastery, you depend closely on direct revel in and eye cues, however at a bigger commercial stage, you want exact, decent methods to assistance mirror every roast profile persistently.

“That’s why investing in well-calibrated technology, with automated controls and data logging, is essential,” he provides. “The team also needs to grow alongside the facility. Technical training, digital process knowledge, and some flexibility in managing new tools are key.”

Leveraging automation

Trendy roasters are most often supplied with automatic scorching functions. As soon as a roaster sparsely dials in a roast profile, the devoted instrument takes keep watch over, adjusting warmth and wind all through the scorching procedure the use of eager information issues.

Those functions have made coaching manufacturing roasters more straightforward than ever prior to, permitting companies to govern labour prices extra carefully. As prices get up around the board, from power to packaging, this hasn’t ever been extra vital.

“I started roasting with an IMF machine in 2001, and since then, it has always been central to my journey, both in artisanal roasting and in scaling up to an industrial operation,” Diego says. “Through the years, IMF has frequently progressed its machines, making them increasingly more exact, environment friendly, and appropriate for all manufacturing wishes.

“The Vortex system, for example, ensures uniform heat distribution for consistent and even roasting, even with larger production volumes, thanks to precise control of the roast profile and Rate of Rise (RoR),” he provides.

A reliance on automation additionally guarantees that companies persistently adhere to feature requirements, even if coaching brandnew body of workers.

What first steps will have to roasters jerk?

As soon as the verdict to scale up has been made, the later step is to create certain the corporate can in reality take care of the predicted expansion.

It’s no longer with reference to the feature of goods and workforce; the roastery location will have to have the ability to take care of the desired volumes.

Deposit capacities and situations for each inexperienced and roasted espresso need to be greater than ample. Inexperienced espresso will have to be saved at a solid temperature to release the danger of feature humility. Processing orders on a bigger scale, due to this fact, calls for a lot more room to collect uncooked fabrics and packaging.

“From an organisational point of view, everything changes as production scales,” Diego explains. “Warehousing, logistics, timing, and making plans will have to all be restructured.

“Economic planning is crucial; growth should be grounded,” he provides. “You need a solid plan with clear figures and realistic goals. Otherwise, the risk is scaling too quickly and putting the entire business at risk.”

Some of the ordinary causes an organization is going into chapter 11 is that it expands too temporarily. Stretching assets to verge of collapse can simply compromise espresso feature and product consistency, in addition to body of workers morale and trade viability.

How apparatus and generation can lend a hand the transition

When scaling up a scorching operation, a area of various apparatus past roasters can assistance backup the corporate all through its preliminary expansion duration.

“From a practical standpoint, the ability to add modules, such as automatic feeding systems, silos, or quality control units, means that the facility can grow with you, without having to start from scratch,” Diego says. “It is a excess merit for roasters having a look to amplify steadily, retaining prices underneath keep watch over date keeping up top quality requirements.

“One of the most interesting aspects of IMF systems is their modularity. It enables you to work with various batch sizes using the same equipment, without compromising precision or consistency in roasting,” he provides. “Whether you’re roasting a specialty micro-lot or selling higher volumes, the machine adapts effectively.”

Specialist apparatus that can be enhanced a roastery’s between-batch protocols may also be similarly as worthy in preserve date, power, and labour. Transferring broad quantities of inexperienced espresso is bodily challenging, so utilising supplementary gadgets like silos and auto loaders can build up skill.

Taking a look forward

When roasters scale up their operations, they most often search a field that may accommodate instant expansion, date additionally making an allowance for the potential of day enlargement.

Making a plan and sight for the trade is an important to keeping up keep watch over over expansion and growing sustainable objectives. Running carefully with skilled scorching plant designers additionally offers espresso manufacturers get admission to to wisdom and insights that would assistance them utility funding capital extra successfully.

“Growing in the coffee industry means finding the right balance between quality, organisation, and technological innovation,” Diego says. “Because of my revel in and decent answers like the ones introduced by means of IMF, I’ve been ready to stand this evolution with out compromising emblem integrity.

“Scaling is possible – provided it’s done with method, vision, and a constant focus on quality,” he provides.

Transferring from small-batch to large-scale scorching is a momentous alternative for a espresso emblem, however the transition comes with its personal distinctive eager of demanding situations.

Pace the not hidden resolution is to shop for a larger device, making an investment in complementary specialist apparatus to lend a hand with the between-batches degree of manufacturing is regularly really helpful.

Loved this? Upcoming learn our article on what roasters need to know when upgrading their facilities.

Picture credit: IMF Roasters, Better Days Coffee Company

Best possible Day by day Grind

Please be aware: IMF Roasters is a sponsor of Best possible Day by day Grind.

Need to learn extra articles like this? Sign up for our newsletter!

Source link