If coffee companies want to build sustainable business models that survive rising inflation and market volatility, then innovation is non-negotiable. The industry has become increasingly competitive, making it all the more important for businesses to stand out and support their own supply chains.

This focus is often on roasters and coffee shops, which are pushed to find differentiated ways to draw in new customers and retain existing ones. While this is undoubtedly true, coffee equipment manufacturers also need to diversify their product offerings just as much as everyone else in the industry.

Pushing for further equipment innovation not only improves the resilience of specialty coffee but also drives the growth of the market, supporting quality and entrepreneurship.

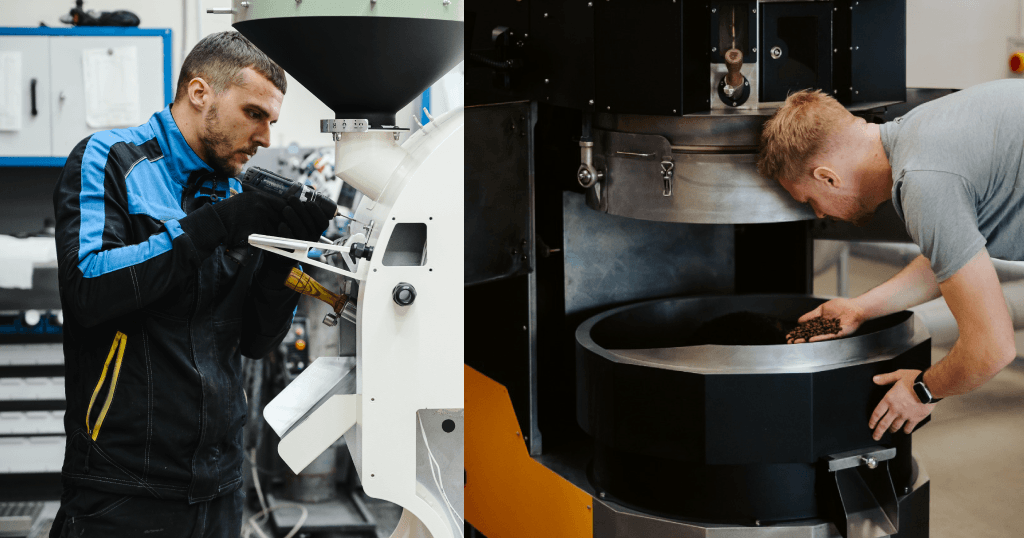

I spoke to Typhoon Roasters’ CEO Nikolas Krutin and Managing Director Daniil Samsonov to learn how roaster manufacturers are evolving to stay competitive.

You may also like our article on how in-store roasting has evolved.

The growing pressure on coffee businesses to stand out

According to the most recent 2024 National Coffee Data Trends (NCDT) report, 45% of US consumers reported drinking a specialty coffee beverage in the past day – an 80% increase since 2011. Specialty coffee consumption is now bigger than ever before, sparking new opportunities for coffee businesses to expand into a burgeoning market.

While this growth drives innovation and quality, it inevitably makes the industry more competitive. Simply offering high-quality coffee is no longer enough; businesses must differentiate themselves in new ways to attract and retain customers. Whether through unique branding, sustainability efforts, direct trade relationships, or exclusive product offerings, having a clear value proposition is essential. Without it, businesses risk blending into an oversaturated market.

“Standing out isn’t just about branding; it’s also about offering a superior product, optimising efficiency, and leveraging the latest technology to maintain quality at scale,” says Daniil Samsonov, the Managing Director at Czech coffee roaster manufacturer Typhoon Roasters.

Economic uncertainty and volatility have become a new normal for coffee businesses, especially following the pandemic, forcing them to adapt and remain agile. Staff shortages, rising inflation and food costs, and record coffee prices have all presented more hurdles to navigate, and there are no signs of these challenges slowing down anytime soon.

Two weeks after hitting US $4.41/lb, the highest number in the history of the C market, arabica futures dipped below $3.80. Towards the end of February 2025, they climbed again, now sitting around $3.90/lb, signalling persistent price volatility that has a huge impact on business operations.

Roasters and coffee shops have adjusted their strategies to accommodate thinner margins and changing consumer behaviour, as people are likely to increase at-home consumption and reduce their average spending.

But it’s not just roasters and coffee shops that need to adapt

Given their proximity to the end consumer, the onus to innovate is often on roasters and coffee shops. Their customer-facing roles mean these businesses need to cater to ever-changing preferences and emerging trends quickly.

But without the support of high-performing, consistent, and reliable equipment, operators will struggle with these efforts. Underperforming and outdated machines hinder a roaster’s ability to improve quality and differentiate their products, putting them at a disadvantage.

This then places more responsibility on manufacturers and equipment brands to also diversify their product offerings, supporting the sustainable growth of the industry as a whole.

“Coffee equipment plays a fundamental role in shaping the quality and efficiency of a roastery. If manufacturers simply produce variations of the same outdated designs, they limit innovation in the industry as roasters and coffee shops are unable to push the boundaries of their creativity,” says Nikolas Krutin, the CEO of Typhoon Roasters. “By diversifying – whether through convection roasting, energy efficiency, or automation – we give roasters the tools they need to stay ahead. Equipment must evolve alongside the businesses that use it.”

To stay competitive, coffee businesses and equipment manufacturers alike are embracing product innovation. While the latter needs to cater to the diverse needs of modern roasters, they also have to stand out against their competitors to attract new clients.

Ultimately, roasting equipment needs to include features and solutions that ensure consistency and maintain quality – two priorities for a roaster of any size.

“Machines need to integrate advanced automation, intelligent software, and precise control systems,” Daniil explains. “Regardless of size, Typhoon machines provide 100% convection roasting, fast batch cycles, and automated features to maximise output and maintain quality.”

Meeting the needs of today’s roasters

Specialty coffee roasters pride themselves on a passion for quality and service – and they expect the same from their equipment suppliers. One of the biggest critiques of manufacturers, regardless of the industry, is subpar service when equipment is broken or parts need to be replaced. A well-built machine backed by fast support and long-term durability is then a major advantage.

Sustainability is another concern for roasters, especially as consumers become increasingly discerning about the brands they buy from. To cater to changing customer demand, roasters need to prove due diligence with their environmental efforts, and equipment can be one of the most effective ways to do this.

“Lower energy consumption, 100% convection roasting, and streamlined workflow solutions help businesses reduce costs and environmental impact,” Daniil tells me. “Unlike traditional drum roasters, which rely on direct or indirect contact heating (as the beans are in contact with the walls of the drum and hot air at the same time), Typhoon machines use fluid bed technology, which supplies a powerful stream of hot air to roast coffee evenly.”

This method reduces energy consumption while enhancing the uniformity of roast development. With energy costs expected to rise another 7% in 2025 in the US, and at similar rates in other regions, reducing overhead costs will become an even bigger priority for roasters.

Investing in equipment that supports the ability to scale operations is also important for roasters. Venturing into wholesale or growing an existing client base can be effective ways to improve resiliency during periods of market volatility and economic uncertainty.

“Equipment should adapt to roasteries’ needs, from different branding options to flexible batch sizes,” Nikolas says. “Each Typhoon model is tailored to support different roasting scales and operational needs.”

The Typhoon 2.5 Pro, for example, is suitable for specialty roasters which focus on micro lots and smaller volumes, while the Typhoon 5 Pro offers a balance between flexibility and productivity ideal for medium-sized operations.

“The Typhoon 10 Pro delivers the performance of a 20kg drum roaster but with improved consistency and lower energy consumption,” Daniil explains, making the machine a suitable option for larger wholesale roasters.

Beyond hardware: Why technology is crucial for product innovation

The design and durability of roasting equipment are key considerations for manufacturers and roasters. Businesses want to invest in high-performance machines that not only meet their production volume requirements but also look good, with the option to customise them to align with brand identity.

But as machines become more advanced, technology is an increasingly important part of the roasting experience, offering roasters the opportunity to diversify their offerings.

“Coffee roasting today isn’t just about hardware – it’s about technology that offers precision and repeatability,” Daniil tells me. “We developed the new Typhoon Roaster Software, which allows users to automate and repeat roasting profiles, adjust airflow and exhaust automatically, and access real-time roasting data that can be integrated with Cropster and Artisan.”

He adds that until 13 April, any purchase of a Typhoon Pro Roaster comes with a free Pro Software Upgrade valued at €2,000, which includes advanced and customised roasting profiles, enhanced control points to monitor and adjust roast parameters in real-time, and seamless integration with popular platforms.

The debate about whether reliance on automation hinders the craft of roasting persists. Still, the industry has widely accepted that embracing technology is the way forward for the growth of specialty coffee.

“Innovation must combine physical and digital solutions to give roasters complete control over quality, efficiency, and scaling their business,” Daniil says. “Typhoon Roasters provide remote access to monitor and maintain machines, ensuring maximum uptime.”

The key to technology in roasting is its ability to streamline operations and ensure repeatable results, freeing up roasters’ time to focus on other essential tasks like inventory management, green quality analysis, and sourcing. Daniil adds that the new Typhoon Roaster Software is currently available at no extra charge, helping roasters further reduce costs.

Additionally, the remote access and maintenance capabilities provide real-time monitoring and troubleshooting, reducing downtime and allowing for proactive equipment management.

In today’s unprecedented coffee industry, marked by record arabica prices and rising inflation, success depends on more than just great coffee. Roasters and cafés must optimise efficiency, maintain consistency, and adapt to changing market demands more than ever before.

Equipment is integral to these efforts, and manufacturers have a duty to cater to the needs of roasters and coffee businesses. By investing in advanced roasting technology – such as automation, intelligent software, and energy-efficient designs – they can streamline operations, reduce costs, and ensure high-quality results at scale, positioning themselves for success in the long term.

Enjoyed this? Then read our article on how convection coffee roasters work.

Photo credits: Typhoon Roasters

Perfect Daily Grind

Please note: Typhoon Roasters is a sponsor of Perfect Daily Grind.

Want to read more articles like this? Sign up for our newsletter!

Source link